In today’s dynamic food industry, where innovation and quality go hand in hand, one ingredient continues to stand out for its versatility and nutritional benefits — Flaking Grits. These coarsely ground corn particles have become a cornerstone in the production of breakfast cereals, snack foods, and even brewing ingredients. With growing consumer demand for natural, gluten-free, and wholesome products, flaking grits are playing an increasingly important role in both domestic and international markets.

What Are Flaking Grits?

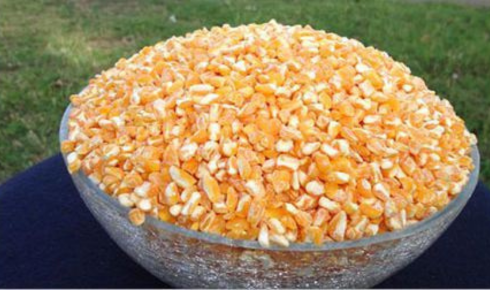

Flaking grits are coarse fractions derived from carefully milled, cleaned, and de-germinated corn kernels. Unlike cornmeal or corn flour, they have a granular structure, which makes them ideal for flaked cereal and snack production. The controlled particle size of flaking grits ensures even cooking and superior flake formation, leading to a consistent texture and taste in the final product.

The unique balance of starch, protein, and fiber in flaking grits makes them not just functional but also nutritious. They are rich in carbohydrates, low in fat, and naturally gluten-free — an ideal choice for health-conscious consumers who seek alternatives to wheat-based foods.

The Manufacturing Process of Flaking Grits

Producing high-quality Flaking Grits involves precision, technology, and expertise. It begins with the selection of premium-grade corn, often non-GMO varieties. The kernels are cleaned thoroughly to remove dust, stones, and other impurities. Next comes the de-germination process, which separates the germ and outer bran layers to yield a pure, endosperm-rich product.

The de-germinated corn is then milled using advanced dry-milling equipment to achieve the desired grit size. The process ensures low heat generation, preserving the natural flavor and nutritional value. The grits are graded, screened, and tested to maintain uniformity, followed by hygienic packaging that protects them from moisture and contamination.

Quality manufacturers also conduct laboratory testing for granulation consistency, color, microbial safety, and moisture control to ensure compliance with international food standards such as ISO, HACCP, and FSSAI.

Applications of Flaking Grits

Flaking grits have become a key ingredient in the production of a wide range of food products. Their most common use is in breakfast cereals, where they are cooked, rolled, and toasted to create golden, crunchy cornflakes. The uniformity of flaking grits ensures that each flake has the same crisp texture and appealing color.

They are also widely used in the snack industry for manufacturing puffed and extruded snacks, coated chips, and corn-based crackers. In breweries, flaking grits are used as adjuncts to add fermentable sugars and improve beer clarity and flavor.

Beyond the food and beverage industries, flaking grits are utilized in the animal feed sector and even in certain industrial applications due to their carbohydrate-rich composition.

Why Quality Matters

In food production, the quality of raw materials determines the final product’s taste, texture, and shelf life. High-quality flaking grits have uniform particle size, low fat content, and excellent cooking behavior. Consistency in grit quality ensures better flake expansion, reduced breakage, and enhanced flavor absorption.

Reputed manufacturers focus on maintaining tight quality control throughout the production process. They use moisture-proof, air-tight packaging to preserve freshness during transport and storage. This attention to detail helps ensure that flaking grits retain their natural color, flavor, and crispness, no matter where they’re shipped.

Global Market Demand for Flaking Grits

The global demand for flaking grits has been steadily increasing, driven by the rise of convenience foods and the popularity of ready-to-eat cereals. Consumers are becoming more health-conscious, seeking nutrient-rich, gluten-free, and minimally processed options. This has led to a surge in the use of corn-based ingredients like flaking grits across various food categories.

Countries in Asia, Africa, and the Middle East are experiencing rapid growth in maize-based food consumption. Meanwhile, major cereal manufacturers in North America and Europe continue to innovate new products that rely heavily on consistent, high-quality grits.

Sustainability and Innovation

As global food production evolves, sustainability has become a core focus. Many producers of flaking grits are adopting eco-friendly practices, such as sourcing corn from responsible farms, reducing water usage during milling, and optimizing energy consumption. These sustainable approaches not only protect the environment but also enhance product quality and traceability.

Final Thoughts

From your morning bowl of cornflakes to the crispy snacks you enjoy in the evening, flaking grits are the unsung heroes behind some of the world’s most popular foods. Their consistency, nutritional value, and adaptability make them indispensable in modern food manufacturing.

As the demand for natural, gluten-free, and sustainable products continues to rise, Flaking Grits will remain a key ingredient driving innovation, quality, and global food security for years to come.